Most Popular Products

Showroom

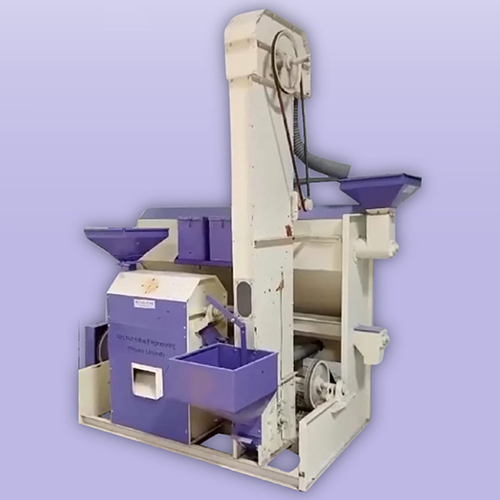

Destoner Cum Grader Cum Aspirator Machine is a combined machine that is widely applied in the treatment of pulses, grains, and seeds. The multiplicity makes it a critical equipment in a dal processing plant. It minimizes contamination and leaves the end product pure, enhancing the quality of grains and dal. These types of machines are made to be long-lasting and easy to maintain, with only occasional cleaning and occasional checks.

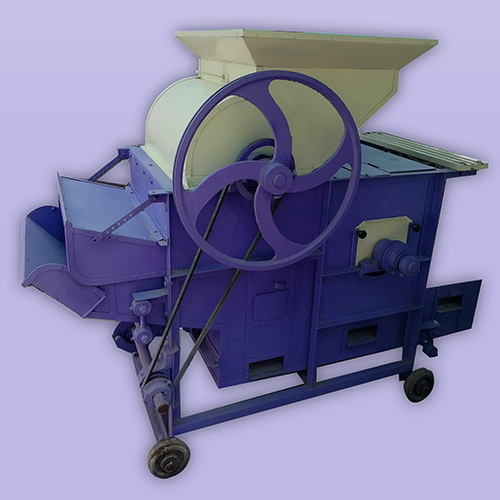

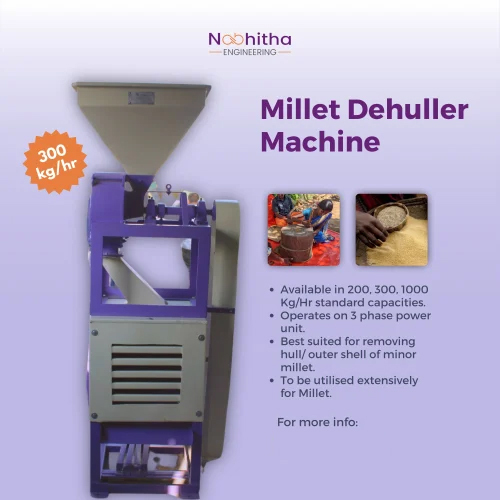

Millet Dehuller Machine is critical in dehusking different varieties of millets. They are appropriate for small-scale processing; ideal for Foxtail and Little millets; simple to operate; suitable for village-level entrepreneurs. Millet Dehuller Machines are especially useful for small-scale processors, women entrepreneurs, and rural communities seeking to value-add millet production.

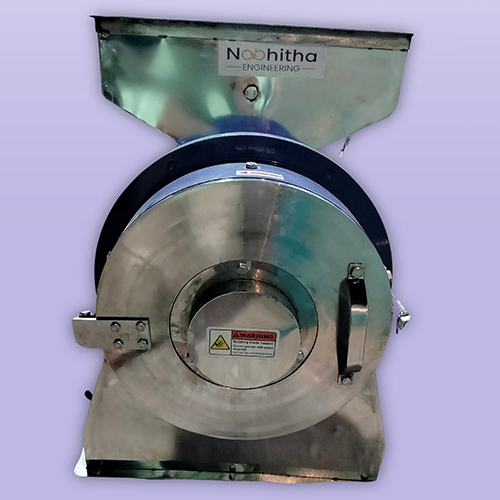

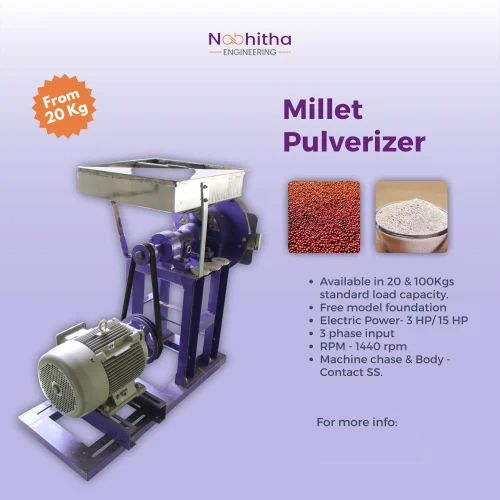

Pulveriser Machine is general-purpose machines used for grinding numerous materials, such as grains, spices, and herbs. They are ideal for high-capacity production lines with low downtime and process large volumes in a short time, thereby saving processing time. They are necessary in domestic as well as commercial environments for applications like flour milling, grinding masala, and processing dry ingredients.

Automatic Packaging Machine provides several advantages across various industries, particularly in manufacturing, food processing, pharmaceuticals, and logistics. This minimizes product wastage and ensures consistency in weight, volume, or quantity. It reduces the demand for manual labor, particularly for repetitive tasks and enhance accuracy results in reduced errors, less product spillage, and less material wastage.

Dal Processing Unit is an industrial facility for dehusking, splitting, polishing, and packaging pulses to clean. It increases product quality, shelf life, and appeal through polishing and packaging. This is utilized for processing raw pulses such as tur (toor), chana, urad, moong, masoor, etc., into edible dal for consumption. Automation features available for large-scale units to increase efficiency.

Dalia Making Machine is employed to mill wheat into dalia (cracked or broken wheat), a common food in traditional as well as health-oriented diets. It reduces the amount of manual labor, thus decreasing labor costs and enhancing efficiency. This machine is made available for food-grade processing with simple cleaning, though. Such machines are often installed in flour mills, food processing industries, and small food businesses.

Dehulling Machine is an important piece of machinery for dal processing plants and other nut/grain processing industries. It reduces manual dehulling requirement, cutting labor and costs related to it. This eliminates the outer husk or hull of seeds, pulses, or grains to prepare them for eating, digestion, and sale. It is more rapid and consistent compared to manual or conventional dehulling processes.

Destoner Machine is an essential machine utilized in grain, pulse, seed, and spice processing plants for removing stones and dense impurities from raw materials. It is ideal for plants that want to maximize manpower and enhance productivity. Its main purpose is to enhance the purity, quality, and safety of the end product by making it stone, clod, and metal particle-free.

Flour Mill Machine is employed to mill raw grains (such as wheat, rice, maize, millet, etc.) into flour or meal for human consumption or animal feed. Automated operations such as feeding, grinding, and flour collection decrease the need for manual labor. The machines are necessary in small-scale home situations as well as large-scale commercial food processing plants.

Groundnut Decorticator is equipment employed to crack or shell the outer pods of groundnuts (peanuts) to reveal the kernels (nuts) from the shells. It peels off the hard external shell or husk from harvested groundnuts with very little kernel damage. It is a central piece of machinery in oilseed processing units, peanut food industries, and small to medium agro-processing enterprises.

Millet De Husker is a machine used to strip the hard outer husk from millet grains like foxtail millet, little millet, kodo millet, barnyard millet, proso millet, and pearl millet. It is suitable for small businesses as well as commercial millet processing plants. These machines are low-maintenance and energy-efficient, making them ideal for rural applications.

Millet Dehullers is a dehusking machine that separates the hard outer husk (hull) from millets. The dehuller strips off this covering, leaving the inner grain (kernel) as it is edible. The units are a motorized unit with small power requirements that assist farmers and processors in going up the value chain.

Millet Processing Unit is a highly promising agro-based enterprise catering to health-focused food patterns, rural development, and green cultivation. It processes raw millets to finished consumer goods such as dehusked grains, millet flour, semolina (rava), flakes, and snacks. The process entails cleaning, dehusking, grading, and packing various kinds of millets such as foxtail, little, kodo, barnyard, proso, finger millet, etc.

Rice Destoner is equipment employed in rice mills to extract stones and other heavier impurities from cleaned or raw paddy and rice. It will no longer be necessary to manually pick out stones, which is inefficient and time-wasting. It creates a clean, high-quality rice that is more desirable to retailers and consumers.

Rice Polisher is equipment utilized to polish rice, beautifying its texture and quality by stripping the bran layer, hence making the rice grains smoother and shiny. Polishing reduces the oil content of the rice bran, thereby prolonging the storage life of the rice. Cooked polished rice cooks more uniformly and has a smoother texture, which is acceptable in most culinary traditions.

|

Nabhitha Engineering Private Limited

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |